YaRRp - Yet another RepRap 3D Printer (Rostock Style)

Designing your (next) 3D printer

Tuesday, December 25, 2012

Season's Greetings

Happy Holidays to everyone. May 2013 bring you and your loved ones good health, lots of love and happiness and good fortune.

Tuesday, December 11, 2012

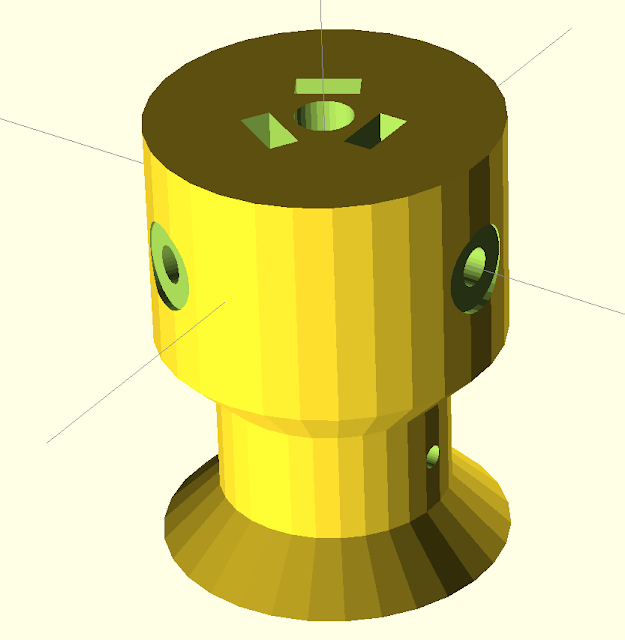

Giveaway 1 - Parametric pulley & idler

Pulley and matching Idler for string driven Rostock Style 3D Printer

Download at: http://www.thingiverse.com/thing:36951

(Enjoy printing. Feedback is welcome)

- STL and SCAD (parametric) format

- Both pulley and idler are preset for M3 nuts

- Parameters are isolated in a separate file

- The ODS file contains some calculations to help you with the parameters and the calculation of the string lenght

Download at: http://www.thingiverse.com/thing:36951

(Enjoy printing. Feedback is welcome)

Labels:

3D Printing,

BOM,

Build,

Design,

giveaways,

OpenSCAD,

Parts,

Thingiverse

Friday, December 7, 2012

Drawing parts (1 / many)

Pending the arrival of the last parts, I decided to start designing some modifications I plan to incorporate in my printer.

First things first though. So activities of yesterday's and today's evenings were:

First things first though. So activities of yesterday's and today's evenings were:

- Install OpenSCAD 3D modeling software which seems to be the favorite amongst the freeware loving builders/makers community.

- Learn the OpenSCAD scripting/programming language. Luckily it comes with the decent manual and there are quite some interesting lessons on Youtube.

- Design a first thing to get a feel of OpenSCAD. I chose to design a 'parameterized' new version of a pulley for a string driven Rostock (preset for M3 nuts and bolts). Came out quite well,... I hope (can't print it yet, so I hope to get some feedback from my readers or from people downloading it from Thingiverse.

- Post the pulley on Thingiverse for everybody to use www.thingiverse.com/thing:36951

Labels:

3D Printing,

Design,

OpenSCAD,

Parts,

Rostock,

Thingiverse,

YaRRP

Monday, December 3, 2012

Build Status Update (part 8/many) - Platform moves!

Just a quick update. After finishing the assembly of the frame and the linear motion, I could finally install and test the platform. Turns out the steppers missed some steps every now and then, but the platform moved. Goal for the day achieved. Next step is taking care of the 'misstepping steppers'.

Below a short video (if there's no pic, it didn't happen).

Below a short video (if there's no pic, it didn't happen).

Wednesday, November 28, 2012

Build Status Update (part 7/many) - First moves!

Just a quick update with a short movie. Today I finished the linear motion. I still some tuning to do though.

As expected I had to fiddle a bit as I am using Spectra instead of belts and replaced the pulleys and idlers with custom printed ones (well to be honest, I got them from Thingiverse). As it turns out the pulleys I had printed are not exactly the right size (scotch tape can do miracles in times of emergency; still not something to keep). Nevertheless job for the day done!

Note to myself: "design your own pulleys and idlers")

Airprinting a Rostock Platform

As expected I had to fiddle a bit as I am using Spectra instead of belts and replaced the pulleys and idlers with custom printed ones (well to be honest, I got them from Thingiverse). As it turns out the pulleys I had printed are not exactly the right size (scotch tape can do miracles in times of emergency; still not something to keep). Nevertheless job for the day done!

Note to myself: "design your own pulleys and idlers")

Airprinting a Rostock Platform

Tuesday, November 27, 2012

Build Status Update (part 6/many) - First moves!

Today my printed parts (red abs) and the rods arrived; so time to start assembling my very own Rostock Delta style 3D printer.

Goal for the day was one moving 'leg', and moving... it did albeit for a very short time!

Before the first attempt, I had to fiddle a bit with the Marlin script though (reversing polarity of the motors). Question to myself: time to make a fork or ask Johann for some enhancements in the standard version?

But as I said, it moved... and it stuttered. But still it moved. By stuttering I mean the top idler was misaligned with the filament pulley, so the spectra 'derailed' but hey; goal of the day reached!

Below is a little video of the very first move. It's an unedited version, so you will also see the filament loosening at the end (Maybe I should have made a 'director's cut').

Goal for the day was one moving 'leg', and moving... it did albeit for a very short time!

Before the first attempt, I had to fiddle a bit with the Marlin script though (reversing polarity of the motors). Question to myself: time to make a fork or ask Johann for some enhancements in the standard version?

But as I said, it moved... and it stuttered. But still it moved. By stuttering I mean the top idler was misaligned with the filament pulley, so the spectra 'derailed' but hey; goal of the day reached!

Below is a little video of the very first move. It's an unedited version, so you will also see the filament loosening at the end (Maybe I should have made a 'director's cut').

Thursday, November 22, 2012

Parts arrived! (part 5/7)

Today the Spectra braided line arrived. It came nicely packages via air mail all the way from China. Unlike most others working on Rostock or Kossel type 3D printers I didn't go for the heavy duty type of line with a 0.6mm diameter and capable of pulling a car. I settled for the 0.2mm sized braided line which should be able to pull 20LB (9,0718474 Kg). After all, the weight of all moving parts combined is just a few hundred grams. We'll see how the line behaves once my very own Rostock type 3D printer is moving. By the way, the line is red as my printed parts will be.

Still on their way:

Still on their way:

- Rods (expected during or juster after the weekend)

- Plastic parts - red (expected during or juster after the weekend)

- PTFE tube (just ordered today; should arrive in 4-5 days)

Subscribe to:

Posts (Atom)